Full-Resolution Image

PulsarOptimizer™ is a set of AI models that maximize metal production by recommending the optimal blending and plant parameters given the ore and operational conditions

It lifts production 2-5% by optimizing the plant operations Learn more

PulsarOptimizer™ traces the ore characteristics from the block model to the plant, allowing for optimal blending and making decisions at the plant ahead of the ore arriving to the plant

PulsarOptimizer™ recalculates the optimal parameters every time conditions change (e.g. ore or operational conditions) Learn more

PulsarOptimizer™ integrates with your control systems (APCs, PLCs). Pulsar Optimizer™ optimizes from the blending and plant paramenters and control systems execute the recommendations in a stable way

While PulsarOptimizer™ has prebuilt modules, no process plant is identical, our team of metallurgists, translators and data scientists co-create the customized models with your operations, metallurgy, IT and maintenance teams

Learn moreWe maintain AI applications and industrial platforms with our team of metallurgists, mine engineers data scients and full stack developers

Our AI models continuously improve to optimize your plant's performance

Models use 4-24 months of historical data and are trained to reach a 95%+ precision

Models predict the plant performance for the next shift (4-6h)

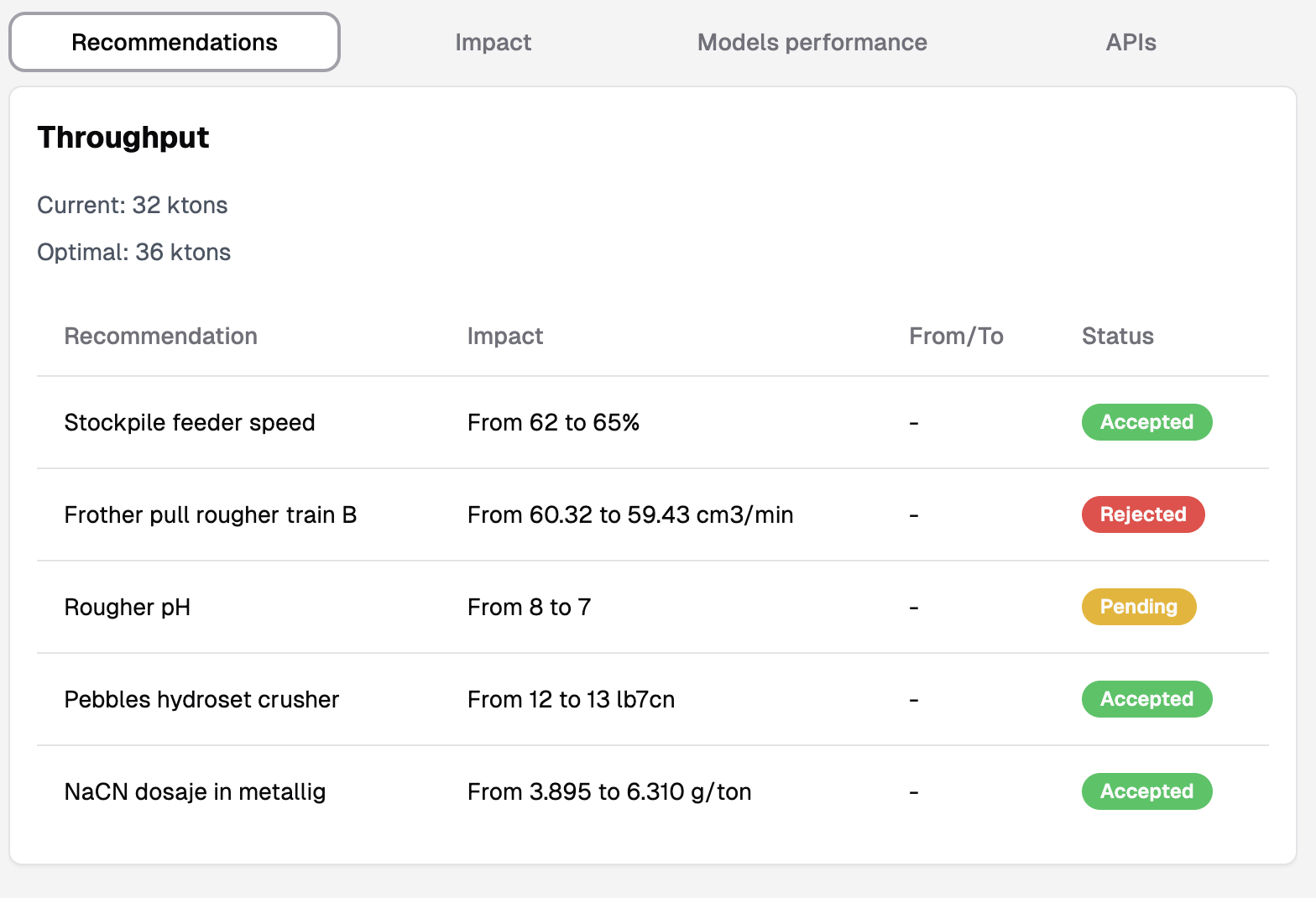

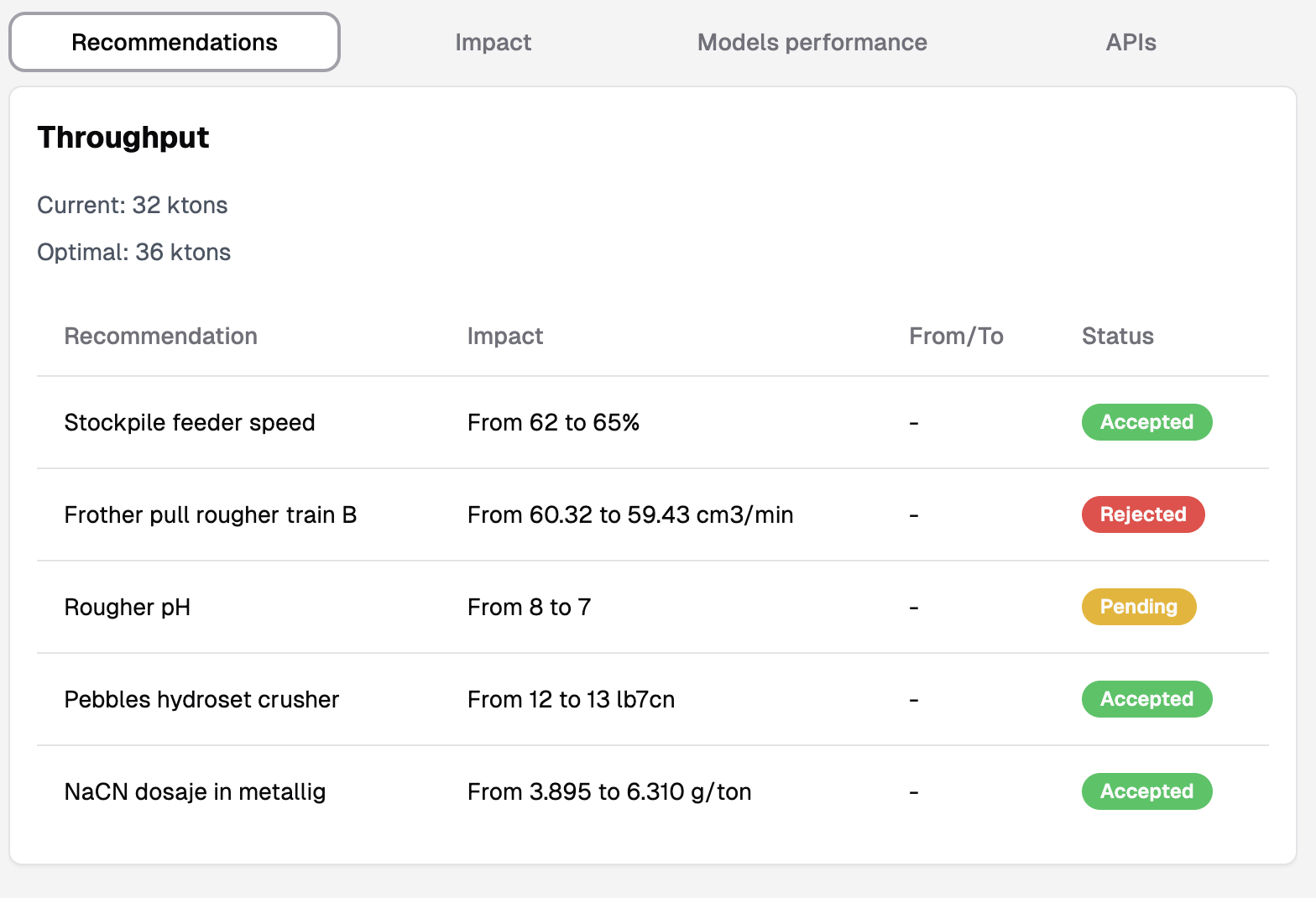

The optimization recommends the optimal blending and setpoints for the plant

Models get retrained when their performance decreases or the plant flowsheet changes, typically every 2-3 months

We are a team at the forefront of integrating advanced AI and control systems to unlock the full potential of your mining assets. With over 55 years of combined experience, our team includes seasoned professionals such as metallurgists, mining engineers, and PhDs in data science. We have had the privilege of working with the top lithium and copper miners. Throughout our careers, we have achieved a combined impact of over 1 billion USD for our clients, delivering measurable and lasting results. Many of our team members are former consultants who have provided strategic guidance to major mining operations, helping to innovate and streamline processes for some of the most prominent companies in the industry. By leveraging AI-driven insights and real-time data, we ensure that our solutions translate into tangible improvements in production enhancements. We work closely with operators, metallurgists, technology and mining teams to ensure that our AI-powered tools are seamlessly integrated with your operations and control systems. Our commitment to collaboration allows us to understand the unique needs of each operation, delivering tailored solutions. By partnering with us, you gain access to a team with a proven track record of success across multiple continents and commodities, ensuring that your operations remain competitive in an ever-evolving industry.

Our customers love working with us

We will assess if you need to add sensors for superior data capture to maximize the insight.

Monthly fee for maintenance and insights.

Yes, models get retrained as new data becomes available. With data enrichment techniques, a few weeks are enough for the system to adapt its way of operating.

No, we provide maintenance and insights as a service.

Site operations: 1 hour per day.

Metallurgist: 2 hours per week.

Energy expert: 1 hour per week.

We'd love to hear from you